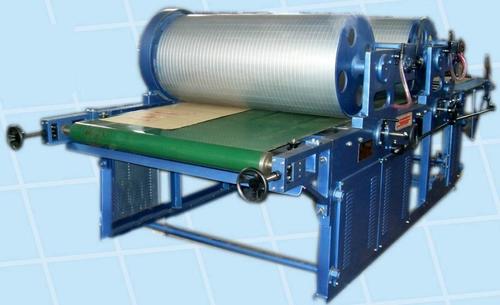

Double Color Flexo Printing Machine

Price 575000 INR/ Set

Double Color Flexo Printing Machine Specification

- Product Type

- Flexo Printing

- General Use

- Corrugated Box Printing Machinery

- Printing Material

- Other

- Type

- Double Color Flexo Printing

- Capacity

- 60 Pcs/min

- Weight (kg)

- 3 Tonne

- Computerized

- No

- Automatic

- No

- Control System

- Manual

- Feeding Size

- 52x72

- Printing Length

- 560 Millimeter (mm)

- Printing Width

- 260 Millimeter (mm)

- Printing Thickness

- 4.97 to 7.2 Millimeter (mm)

- Voltage

- 380-440 Volt (v)

- Feature

- High Efficiency

- Color

- Custom

Double Color Flexo Printing Machine Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- Mundra Port

- Payment Terms

- Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

- Supply Ability

- 2 Sets Per Month

- Delivery Time

- 40-45 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wrap in BOPP Film and Wooden Boxes

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- ISO, CE

About Double Color Flexo Printing Machine

BOXMAC Double Colour Paper Flexo Printer Machine

This equipment provides 2 Colour Printing. High precision anilox roll is fixed. Single sheet manual feeding is there. Ideal for printing on Kraft paper & Corrugated Board. Uniform spreading and controlled flow of ink.

Size: 52 x 72

Technical Specifications:

(A)Anilox Roller & Rubber Roller

(B) Stainless Steel Ink Tray

(C) 5 H.P. Motor

(D)With Variable Speed A.C. Drive

(E) With Oil Lubricant Pump

(F) With Canvas Belt

(G)Make of Bearings NTN / SKF / NBC

(H)With all Standard Accessories Complete.

Efficient Double Color Printing

This flexo machine stands out for its ability to execute vivid double color prints with precision. Designed for corrugated box applications, it enhances production efficiency, delivering clear and consistent results on every run. Its manual controls prioritize reliability and operator skill, suitable for diverse industrial environments.

Built for Versatility

The machines customizable color options and adjustable printing length provide flexibility across packaging requirements. Whether producing small batches or large volumes, its 60 pcs/min capacity and support for various thicknesses make it a versatile asset for any corrugated box manufacturing unit.

FAQs of Double Color Flexo Printing Machine:

Q: How does the Double Color Flexo Printing Machine operate?

A: This machine employs manual controls for all functions, enabling operators to adjust settings easily and maintain consistent output. Its double color flexo process uses two color stations to deliver vibrant prints on corrugated boxes.Q: What is the printing process of this machine?

A: The machine utilizes flexographic technology, transferring ink from flexible plates to the substrate. Operators manually feed sheets of corrugated board within the 52x72 feeding size, and the machine prints with a thickness range between 4.97 to 7.2 mm.Q: When is this machine ideal for use?

A: Its best suited for situations where double color printing is required on corrugated boxes, especially in medium-scale operations where manual control ensures precise adjustments and quality assurance.Q: Where can the Double Color Flexo Printing Machine be installed?

A: This model is designed for industrial facilities engaged in box manufacturing, such as packaging plants, export warehouses, and supplier units primarily in India. Its weight and dimensions may require a dedicated installation space.Q: What are the main benefits of using this printing machine?

A: Operators gain high efficiency (up to 60 pcs/min), flexible color customization, and compatibility with a range of printing thicknesses. Its reliability and manual controls allow for tailored adjustments per production batch, enhancing overall consistency.Q: How is printing thickness managed on this machine?

A: The machine enables users to adjust printing thickness between 4.97 and 7.2 mm using the manual control system, ensuring optimal print quality for different corrugated boards.Q: Is the Double Color Flexo Printing Machine computerized or automatic?

A: No, both control and operation are fully manual. This allows for direct operator involvement and finely tuned adjustments throughout the printing process.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

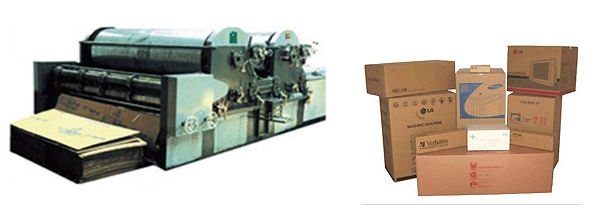

More Products in Flexo Printing Machinery Category

Roll To Sheet Flexo Printing Machine

Price 950000.00 INR / Set

Minimum Order Quantity : 1 Set

Product Type : Roll to Sheet Printing Machine

Computerized : No

Automatic : Yes

Three Color Flexo Printing Machine

Price 850000 INR / Set

Minimum Order Quantity : 1 , , Set

Product Type : Three Color Flexo Printing Machine

Computerized : Yes

Automatic : Other, SemiAutomatic/Automatic (Configurable)

Double color flexo printing machine

Price Range 440000.00 - 1335000.00 INR / Set

Minimum Order Quantity : 1 Set

Product Type : Double color flexo printer

Computerized : No

Automatic : No

Paper Flexo Printing Machine

Product Type : Paper Flexo Printing Machine

Computerized : Yes

Automatic : Other, Semi Automatic / Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS