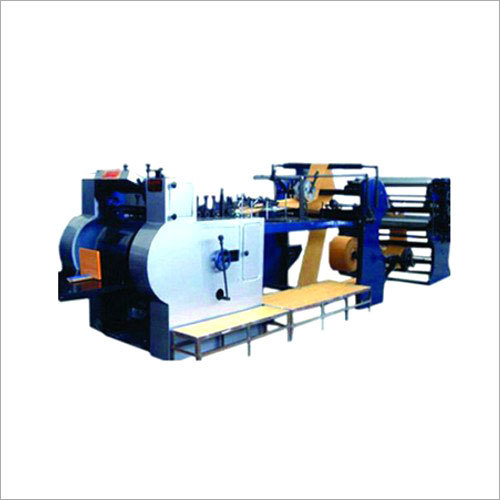

Four Colour Bag Making Machine

Price 47500 INR/ Set

Four Colour Bag Making Machine Specification

- Product Type

- Four Colour Bag Making Machine

- General Use

- Used for making multi-colour printed bags from film

- Efficiency

- High productivity with multi-bag output per minute

- Weight (kg)

- Approx. 2200 kg

- Automatic Grade

- Automatic

- Drive Type

- Electric motor driven

- Bag Type

- Shopping bags, carry bags, packaging bags

- Computerized

- Yes

- Photoelectric Correction

- Enabled

- Film Length Counter

- Digital film length counter provided

- Bag Length

- 300 mm to 900 mm (adjustable)

- Power

- 10 kW

- Voltage

- 220V - 380V

- Material

- Suitable for LDPE, HDPE, PP films

- Dimension (L*W*H)

- 4500 x 1800 x 2100 mm

- Feature

- Multi-colour Flexo printing, automatic cutting, high speed

- Color

- Standard industrial finish (grey/blue)

- Noise Level

- Less than 78 dB

- Max. Bag Width

- 850 mm

- Number of Printing Stations

- 4 (Flexo printing system)

- Sealing Type

- Heat sealing

- Control Panel

- PLC controlled with touch screen

- Rewinder Type

- Automatic tension rewinder

- Max. Printing Speed

- 80 meters/min

- Unwinder Type

- Heavy-duty dual unwinders

- Installation Support

- On-site installation and training available

- Temperature Control

- Precise digital temperature control

Four Colour Bag Making Machine Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 3 Sets Per Month

- Delivery Time

- 30 Days

About Four Colour Bag Making Machine

Advanced Multi-Colour Flexo Printing System

Featuring four dedicated printing stations, this machine delivers high-quality, vibrant prints on each bag. Its Flexo technology ensures crisp, consistent results even at high speeds, making it ideal for packaging, retail, and branding requirements. The system caters to LDPE, HDPE, and PP films, providing versatility and reliability for various bag production needs.

Efficient Production and User-Friendly Operation

Engineered for maximum output, this machine boasts an automatic grade with electric motor drive and computerized controls. Operators benefit from the PLC-controlled touch screen, digital film length counter, precise digital temperature control, and photoelectric correction. The result is simplified workflow, reduced downtime, and consistent quality, supported by comprehensive on-site installation and training.

FAQs of Four Colour Bag Making Machine:

Q: How does the Four Colour Bag Making Machine improve production efficiency?

A: With its automatic grade, electric motor-driven operation, and high printing speed of up to 80 meters per minute, the machine enables multi-bag output every minute. The computerized PLC touch screen control streamlines adjustments, minimizing manual intervention and maximizing productivity.Q: What types of films and bag sizes can this machine handle?

A: The machine is suitable for LDPE, HDPE, and PP films. It accommodates bag widths up to 850 mm and bag lengths ranging from 300 mm to 900 mm, making it adaptable for shopping, carry, and packaging bag production.Q: When should precise digital temperature control be adjusted during the bag making process?

A: Temperature adjustments are typically managed during setup and operation via the digital control panel to ensure optimal heat sealing. This is crucial when switching film materials or bag specifications to maintain seal integrity and quality.Q: Where is installation support provided for this machine?

A: On-site installation and training support are available throughout India. This ensures that operators can efficiently learn setup, operation, and troubleshooting for seamless production.Q: What is the process for printing and cutting bags on this machine?

A: The process begins with film unwinding on heavy-duty dual unwinders, followed by multi-colour Flexo printing across four stations. Printed film then moves to heat sealing, automatic cutting, and is finally rewound with automatic tension control for uniform output.Q: How does the PLC-controlled touch screen panel benefit users?

A: The PLC-controlled touch screen enables intuitive operation, rapid settings adjustment, and real-time system monitoring. This results in enhanced control over printing parameters, temperature, and film length, reducing errors and increasing efficiency.Q: What are the primary benefits of using this machine for bag manufacturing?

A: Key benefits include high-speed multi-bag production, precise multi-colour printing, automatic cutting and sealing, low noise operation (under 78 dB), and reliable performance with computerized and PLC-controlled features. These enable consistent quality and easy scalability for manufacturers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bag Making Machine Category

Paper Bag Forming Machine

Price 650000.00 INR / Set

Minimum Order Quantity : 1 Set

Bag Type : Paper Bag

Drive Type : Electric

Product Type : Paper bag

Automatic Grade : Semi Automatic

Automatic Square Bottom Paper Bag Making Machine

Price 4500000 INR / Set

Minimum Order Quantity : 1 Set

Bag Type : Paper Bag

Drive Type : Electric

Product Type : Automatic

Automatic Grade : Automatic

BAGMAC Senior 1 Without Printing Attachment

Price 590000.00 INR / Set

Minimum Order Quantity : 1 Set

Bag Type : Paper Bag

Drive Type : Electric

Product Type : V BOTTOM BAG MAKING MACHIEN

Automatic Grade : Semi Automatic

Heavy Duty Paper Bag Making Machine

Price 475000.0 INR / Set

Minimum Order Quantity : 1 Set

Bag Type : Other, Square bottom/flat bottom paper bags

Drive Type : Other, Electric motor

Product Type : Heavy Duty Paper Bag Making Machine

Automatic Grade : Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS