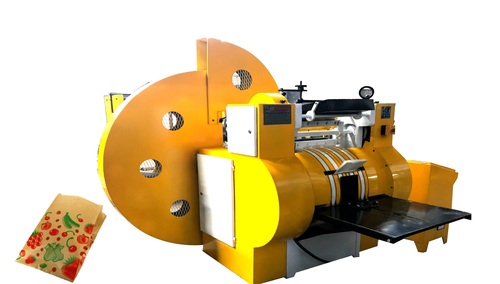

Fully Automatic Paper Bag Making Machine

Price 47500 INR/ Set

MOQ : 1 Set

Fully Automatic Paper Bag Making Machine Specification

- Product Type

- Fully Automatic Paper Bag Making Machine

- General Use

- Manufacturing paper bags with automatic operation

- Efficiency

- High efficiency up to 180 bags per minute

- Weight (kg)

- Approx. 3000 kg

- Automatic Grade

- Fully Automatic

- Drive Type

- Electric

- Bag Type

- Shopping Bags, Grocery Bags, Food Bags

- Computerized

- Yes

- Photoelectric Correction

- Yes

- Film Length Counter

- Yes

- Bag Length

- 180 mm to 460 mm (adjustable)

- Power

- Approx. 7.5 kW

- Voltage

- 380 V, 3 Phase, 50/60 Hz

- Material

- Kraft paper, art paper, laminated paper

- Dimension (L*W*H)

- 8500 mm x 2100 mm x 1800 mm

- Feature

- Touchscreen operation, automatic counting, high-speed servo control

- Color

- Industrial Grey with blue accents

Fully Automatic Paper Bag Making Machine Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 3 Sets Per Month

- Delivery Time

- 30 Days

About Fully Automatic Paper Bag Making Machine

Fully Automatic Paper Bag Making Machine is a heavy duty industrial unit which makes it very easier to make large number of high quality kraft bags in various customizable lengths as per the requirement. It can be easily controlled by a single operator with the help an electrical control panel. The structural frame and the component parts of this machine are manufactured by using heavy duty engineering materials which imparts greater strength and rigidity for longer service life.

Advanced Automation for Consistent Quality

Equipped with PLC and touchscreen controls, this machine offers fully automated operation, from paper feeding to bag stacking. The system ensures precise alignment thanks to photoelectric correction, reducing manual intervention and error. Its automated glue application and counting systems streamline production, guaranteeing consistent and high-quality paper bags suited for various uses, such as retail and food packaging.

Versatile Bag Production for Multiple Applications

With adjustable bag width (70320 mm), bottom width (30130 mm), and bag length (180460 mm), this machine accommodates a wide range of product needs. It efficiently handles various kinds of paper, including kraft, art, and laminated papers, making it suitable for manufacturing shopping, grocery, and food bags in a single setup. This flexibility enables manufacturers to cater to diverse customer demands.

High Efficiency and User-Friendly Operation

Operating at speeds of up to 180 bags per minute, the machine maximizes productivity while maintaining low noise levels ( 75 dB). The intuitive touchscreen interface provides easy access to all settings, enabling quick adjustments and monitoring even by a single operator. The advanced servo control and robust build ensure reliable performance and minimal downtime, contributing to high operational efficiency.

FAQs of Fully Automatic Paper Bag Making Machine:

Q: How does the fully automatic paper bag making machine increase manufacturing efficiency?

A: The machine streamlines the entire bag-making process, featuring automatic feeding, hot melt glue application, bag collection, and counting. With a speed of up to 180 bags per minute and user-friendly touchscreen control, it significantly reduces manual labor and production time, allowing a single operator to oversee high-volume operations.Q: What types and sizes of bags can be produced with this machine?

A: You can produce shopping, grocery, and food bags within a bag width range of 70320 mm, bottom width range of 30130 mm, and adjustable bag lengths of 180460 mm. The machine is compatible with kraft, art, and laminated paper, supporting paper thickness from 35150 gsm.Q: When should I choose this machine over semi-automatic bag makers?

A: This fully automatic paper bag making machine is ideal when your business requires high-volume, consistent quality output with minimal operator intervention. Its automation, high speed, and sophisticated control features make it suitable for manufacturers aiming to boost efficiency, reduce errors, and scale production.Q: Where is this machine typically used?

A: It is commonly used in factories, industrial workshops, and commercial packaging production units, especially by manufacturers, exporters, traders, and suppliers in the shopping, grocery, and food packaging sectors.Q: What is the process for setting up and operating the machine?

A: Install the machine on a stable floor, ensure proper 380V, 3-phase power supply, and connect the compressed air line (0.6 MPa). Load the appropriate paper roll (up to 900 mm width), input the desired bag dimensions via the touchscreen, and let the PLC-controlled system manage feeding, forming, gluing, and stacking. Minimal manual intervention is required throughout operation.Q: What are the main benefits of using this paper bag making machine?

A: Users benefit from high productivity, precise control, low noise operation, and adaptable settings for various bag types and sizes. The automatic glue, counting, and stacking systems enhance efficiency, while the robust build and computerized controls reduce downtime and maintenance costs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Bag Making Machine Category

BAGMAC Automatic Square Bottom Paper Bag Making Machine

Minimum Order Quantity : 1 Set

General Use : Paper Bag Forming Machine

Power : 20 Horsepower (HP)

Color : Two Color

Computerized : Yes

BAGMAC Sharp Bottom Paper Bag Making Machine

Minimum Order Quantity : 1 Set

General Use : Paper Bag Forming Machine

Power : 2 Horsepower (HP)

Color : without printing

Computerized : No

Paper Bag Making Machine

Price 920000.00 INR / Piece

Minimum Order Quantity : 1 Piece

General Use : GROCERY BAG, SHOPPING BAG, FOOD BAG

Power : 5 Horsepower (HP)

Color : CUSTOMER

Computerized : Yes

BAGMAC V Bottom Paper Bag Making Machine with Two Color Flexo Printing Attachment

Minimum Order Quantity : 1 Set

General Use : Paper Bag Forming Machine

Power : 3 Horsepower (HP)

Color : Two Color

Computerized : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS