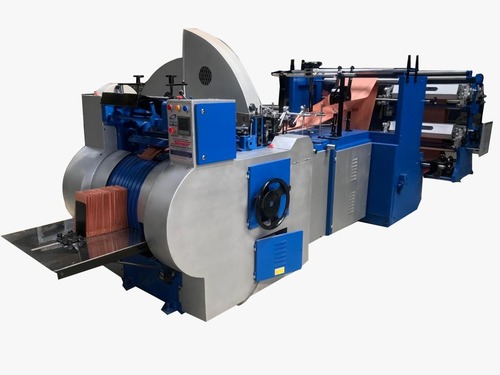

Paper Bag Making Machinery

Price 590000.00 INR/ Piece

Paper Bag Making Machinery Specification

- Product Type

- Paper Bag Making Machinery

- General Use

- Manufacturing paper bags for commercial packaging

- Efficiency

- High output with low wastage

- Weight (kg)

- Approx. 1200 kg

- Automatic Grade

- Automatic

- Drive Type

- Electric

- Computerized

- Yes

- Photoelectric Correction

- Yes

- Film Length Counter

- Yes

- Power

- 6.5 kW

- Material

- Paper (kraft, white, coated)

- Dimension (L*W*H)

- 4200 x 1900 x 1700 mm

- Feature

- Automatic tension control, advanced touch panel

- Color

- Standard industrial finish (blue/white/grey)

Paper Bag Making Machinery Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 4 Pieces Per Month

- Delivery Time

- 30-40 Days

About Paper Bag Making Machinery

Paper Bag Making Machinery

Holding years of experience and knowledge in this industry, our company has been able to mark its strong presence in the market as one of the most excellent manufacturers and exporters of Paper Bag Making Machinery. Widely used in industries to manufacture paper bags, our offered range is known for its remarkable features such as less power consumption, high operational fluency and superior performance. We are offering this Paper Bag Making Machinery to our clients at competitive prices and that too within the given time frame.

Further Details

Our paper bag making machine is used to manufacture paper bags. These machines are corrosion resistant and have a high production capacity. With a reel diameter of 500mm they consume low power and can be fabricated according to clients requirements.

Production Capacity - Line Speed of 8-25 meters per minute Depend on Laminate

Operational Space required - W-2 met.x L-6.5 met x H-3 met Approx.

Precision Engineering for Reliable Bag Production

Equipped with a high-precision rotary blade cutting system and automatic bottom folding, this paper bag making machine guarantees uniform bag dimensions and dependable quality. The automatic gluing and advanced touch panel streamline operations, resulting in fewer manual interventions and consistent output every cycle.

Operator-Friendly and Safe Design

Operated through a modern PLC interface, only one person is needed to manage the entire process. Key safety features, including emergency stops and interlock guards, combine with low noise and automatic lubrication to deliver a secure and ergonomic working environmentan ideal solution for efficient, high-volume production.

Efficiency and Versatility for Commercial Packaging

Designed to handle kraft, white, and coated paper within a wide specification range, this machinery is perfect for diverse commercial packaging needs. Its automatic grade and photoelectric correction minimize material wastage while maximizing throughput, empowering businesses to maintain top-grade production with, industry-standard CE certification.

FAQs of Paper Bag Making Machinery:

Q: How does the automatic gluing system work in this paper bag making machine?

A: The inline automatic gluing system precisely applies adhesive to paper during bag formation, ensuring uniform adhesion and seamless bag integrity without the need for manual application.Q: What materials are compatible with this machine?

A: The machinery supports a wide range of paper typesincluding kraft, white, and coated varietiesallowing flexibility for diverse packaging requirements in commercial settings.Q: When should the lubrication system be maintained?

A: The machine features an automatic centralized lubrication system, which minimizes manual maintenance. Regular checks are recommended as per the manufacturers guidelines to ensure optimal operation.Q: Where is this machinery typically used?

A: This machine is commonly deployed in manufacturing plants, factories, and packaging units where commercial paper bags are produced for retail, food, and other packaging industries.Q: What is the process for changing bag dimensions?

A: Adjustments for bag width, length, and bottom folding can be made through the PLCs digital display interface, allowing operators to quickly set new parameters according to production needs.Q: How does the safety system protect the operator during operation?

A: Safety mechanisms include an emergency stop button and interlock guards, which instantly halt machine functions and secure moving parts in case of irregularities or emergencies.Q: What are the key benefits of using this automatic paper bag making machine?

A: Key benefits include high production efficiency, low material wastage, a single-operator interface, advanced tension and quality control, and compliance with CE safety and production standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bag Making Machine Category

BAGMAC Square Bottom Paper Bag Making Machine

Price 5900000 INR / Set

Minimum Order Quantity : 1 Set

General Use : Paper Bag Forming Machine

Color : Two Color

Automatic Grade : Automatic

Dimension (L*W*H) : 27.9*17*7.8 Inch (in)

Grocery Food Paper Bag Making Machine

Minimum Order Quantity : 1 Set

General Use : Paper Bag Forming Machine

Color : without printing

Automatic Grade : Semi Automatic

Dimension (L*W*H) : 276x91x67 Inch (in)

PLC Servo Based High Speed Paper Bag Making Machine

Minimum Order Quantity : 1 Set

General Use : Paper Bag Forming Machine

Color : Nil

Automatic Grade : Automatic

Dimension (L*W*H) : 35*30*100 Centimeter (cm)

Automatic Paper Bags Forming Machine

Minimum Order Quantity : 1 Piece

General Use : Making paper bags of various sizes and types for packaging

Color : Industrial grey/blue (customizable)

Automatic Grade : Automatic

Dimension (L*W*H) : Approx. 6000 x 1500 x 1800 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS