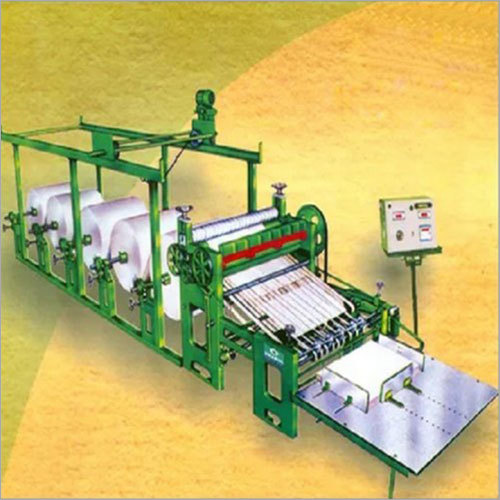

Digital Rotary Sheet Cutter

Price 425000.00 INR/ Set

Digital Rotary Sheet Cutter Specification

- Drive Motor

- High-torque Servo Motor

- Product Type

- Industrial Sheet Cutter

- General Use

- Accurate Sheet Cutting for Printing and Packaging

- Material

- Mild Steel, Aluminium, Composite

- Type

- Rotary Sheet Cutter

- Capacity

- Continuous Operation, 8 hours/day

- Weight (kg)

- 135 kg

- Computerized

- Yes

- Automatic

- Fully Automatic Operation

- Cutting Speed

- Up to 1200 mm/min

- Cutting Thickness

- Up to 3 mm (Material Dependent)

- Cutting Function

- Automated Rotary Cutting

- Cooling System

- Air Cooling

- Drive Type

- Servo Motor Drive

- Voltage

- 220V / 50Hz

- Dimension (L*W*H)

- 1100 mm x 850 mm x 1200 mm

- Feature

- High-Precision, Digital Control, User-Friendly Interface

- Color

- Industrial Grey with Black Accents

- Motor

- Brushless Servo Motor

- Mechanical Precision

- 0.1 mm

- Software Detail

- Proprietary Digital Cutting Software Compatible with Windows

- Cutting Method

- Rotary Blade, Sheet Feed

- Control System

- Digital Interface with Parameter Memory

- Cutting Area

- 500 mm x 700 mm

- Cutting Material

- Paper, Cardboard, Vinyl, Thin Plastics

- Display Interface

- LCD touchscreen panel

- Power Consumption

- Approx. 450W

- Safety Features

- Emergency stop, safety covers, overload protection

- Operating Humidity

- 20% - 80% RH

- Installation

- Desktop/benchtop design

- Sheet Loading Capacity

- Single or stacked manual feed

- Operating Temperature Range

- 10°C - 35°C

- Connectivity

- USB & Ethernet

- Supported File Formats

- .plt, .dxf, .cdr, .ai

- Noise Level

- <65 dB during operation

Digital Rotary Sheet Cutter Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 4 Pieces Per Month

- Delivery Time

- 45-60 Days

About Digital Rotary Sheet Cutter

Intuitive LCD Touchscreen Interface

The cutters LCD touchscreen simplifies operation, allowing users to set precise parameters, view file previews, and adjust jobs with ease. With digital memory, frequent cutting profiles can be saved and recalled, streamlining repetitive tasks and reducing setup timemaking it especially user-friendly for both seasoned operators and newcomers.

Robust Construction & High Precision

Engineered using a combination of mild steel, aluminium, and composite materials, this rotary sheet cutter delivers exceptional durability. The servo-driven rotary cutting system ensures reliable high-precision cutting to within 0.1 mm, meeting exacting standards in both high-volume and specialized sheet processing environments.

Versatile Material Handling & Continuous Operation

With the ability to cut various materials, including paper, cardboard, vinyl, and thin plastics, the machine adapts to diverse project needs. Designed for continuous operation up to 8 hours daily, it supports both single and stacked manual feeding, maximizing output and minimizing downtime.

Comprehensive Safety & Connectivity

Prioritizing operator safety, the sheet cutter incorporates emergency stop mechanisms, safety covers, and overload protection. Its desktop/benchtop design fits flexible workspaces, while USB and Ethernet connectivity offer seamless integration into existing workflows and networks.

FAQs of Digital Rotary Sheet Cutter:

Q: How does the Digital Rotary Sheet Cutter ensure precise cutting results?

A: The cutter utilizes an advanced servo motor drive and a high-precision rotary blade mechanism, delivering consistent mechanical accuracy within 0.1 mm. Its digital control interface and proprietary software allow for precise parameter adjustments tailored to each job.Q: What types of materials can be processed with this sheet cutter?

A: This machine is designed to cut a variety of sheet materials, including paper, cardboard, vinyl, and thin plastics up to 3 mm thick, making it ideal for printing and packaging applications.Q: When and where can the cutter be installed for optimal use?

A: The compact desktop/benchtop design enables easy installation in printing shops, packaging facilities, or offices. For optimal performance, operate the cutter in environmental conditions between 10C-35C and 20%-80% relative humidity.Q: What is the sheet loading process for this machine?

A: Sheets can be manually fed either singly or in stacks, depending on job requirements. The machines user-friendly interface guides the operator through each step, ensuring smooth and efficient material loading and feeding.Q: How does the machine handle safety during operation?

A: Operator safety is assured through multiple features, including an emergency stop button, safety covers around critical areas, and overload protection, which immediately halts the cutter if it detects abnormal conditions.Q: What are the connectivity and file compatibility options?

A: Data transfer is facilitated through USB and Ethernet ports. The cutter supports common design file formats like .plt, .dxf, .cdr, and .ai, and operates with proprietary Windows-compatible digital cutting software.Q: What benefits does this cutter offer to printing and packaging businesses?

A: Users benefit from high-precision, automated cutting with minimal noise (<65 dB), efficient workflow integration, versatile material support, robust safety features, and reduced setup timesenhancing productivity and quality while ensuring operator safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paper Roll To Sheet Cutting Machine Category

P.I.V. Reel to Sheet Cutter Machine

Price 425000.00 INR / Set

Minimum Order Quantity : 1 , , Piece

Software Detail : PLC Programmed Automation

Cutting Material : Paper, Film, Nonwoven, Laminates

Mechanical Precision : 0.5 mm

Cutting Area : 1200 mm x 1800 mm

Paper Roll to Sheet Cutting Machine with 5 Roll Stand

Price 425000.00 INR / Set

Minimum Order Quantity : 1 , , Piece

Software Detail : PLC controlled system

Cutting Material : Paper, thin board

Mechanical Precision : 0.5 mm

Cutting Area : Up to 1200 mm width

Hand Board Cutter Machine

Price 425000.00 INR / Set

Minimum Order Quantity : 1 Piece

Software Detail : Manual Operation

Cutting Material : Paper Board, Card Board

Mechanical Precision : 0.2 mm

Cutting Area : 600 mm x 400 mm

Programmatic Rotary Sheet Cutter Machine

Price 425000.00 INR / Set

Minimum Order Quantity : 1 Piece

Software Detail : PLC based Control System

Cutting Material : Paper, Board, Kraft

Mechanical Precision : 0.5 mm

Cutting Area : Up to 1500 mm width

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free