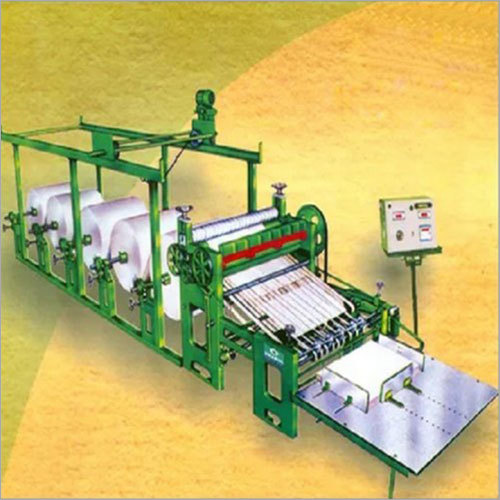

Programmatic Rotary Sheet Cutter Machine

Price 425000.00 INR/ Set

Programmatic Rotary Sheet Cutter Machine Specification

- Drive Motor

- Servo Motor

- Product Type

- Programmatic Rotary Sheet Cutter

- General Use

- Sheet cutting for paper/board converting

- Material

- Paper, Duplex Board, Kraft Paper, etc.

- Type

- Rotary Sheet Cutter Machine

- Weight (kg)

- 1800 kg

- Computerized

- Yes

- Automatic

- Fully Automatic

- Cutting Speed

- Up to 300 cuts/min

- Cutting Thickness

- Up to 500 gsm

- Cooling System

- Fan Air Cooled

- Drive Type

- Servo Motor Driven

- Dimension (L*W*H)

- 3800 x 2100 x 1600 mm

- Feature

- High precision, high speed, automatic operation

- Color

- Blue/Grey

- Motor

- 4 kW (5 HP)

- Mechanical Precision

- 0.5 mm

- Software Detail

- PLC based Control System

- Cutting Method

- Rotary Shearing

- Control System

- Electronic PLC Based

- Cutting Area

- Up to 1500 mm width

- Cutting Material

- Paper, Board, Kraft

Programmatic Rotary Sheet Cutter Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 4 Pieces Per Month

- Delivery Time

- 45-60 Days

About Programmatic Rotary Sheet Cutter Machine

Programmatic Rotary Sheet Cutter Machine

Owing to our wide experience in this domain, our company is counted among the foremost manufacturers and exporters of Programmatic Rotary Sheet Cutter Machine. At our well developed manufacturing, our offered range of rotary sheet cutter machine is manufactured and designed to give maximum efficiency and reliable performance with minimum maintenance cost. This Programmatic Rotary Sheet Cutter Machine is widely used in various industries and can be availed from us at negotiable prices.

Further Details:

We offer electronic auto reel sheet cutter without any PIV gear box. No need to change any gears for sizes totally electronic. This machine is designed for perfect accuracy high production and sharp cutting of single face corrugating board without damaging the flutes as well as plane paper. Electronic devices are provided to ensure accurate cutting of the sheet to the required length.

Technical Specifications

| Size | Power | Floor Space | Weight (App) |

| 45 | 3HP | 90X 53 | 1400kg |

| 54 | 3HP | 90X 61 | 1600kg |

| 64 | 4HP | 90X 70 | 2000kg |

| 74 | 4HP | 90X 80 | 2400kg |

Superior Precision & High-Speed Output

This rotary sheet cutter features state-of-the-art servo motor drives and a PLC-based control system, delivering outstanding accuracy and speed. Achieve up to 300 cuts per minute with mechanical precision within 0.5 mm, ensuring product consistency and minimal waste. The automated control streamlines complex cutting sequences for industrial paper and board converting.

Versatile Material Compatibility

Engineered to handle a wide selection of materials, the cutter processes paper, duplex board, Kraft, and similar stock up to 500 gsm in thickness. Its 1500 mm cutting width accommodates large-format sheets, making it suitable for commercial printing and packaging converters seeking adaptability in production.

Plug-and-Play Fully Automatic Operation

Featuring a user-friendly computerized interface, this rotary cutter is simple to set up and operate. The PLC-based system automates sheet feeding and cutting, reducing manual intervention and operator fatigue. A servo-driven mechanism ensures reliable performance and optimal throughput in demanding manufacturing settings.

FAQs of Programmatic Rotary Sheet Cutter Machine:

Q: How does the PLC-based control system enhance the operation of the rotary sheet cutter?

A: The PLC-based control system ensures precise synchronization and automated operation. It manages sheet feeding, cutting sequences, and servo motor coordination, allowing users to achieve high throughput, consistent cut lengths, and minimal error without extensive manual input.Q: What materials and thicknesses can this rotary sheet cutter process?

A: This machine is capable of cutting various materials such as paper, duplex board, and Kraft paper, supporting thicknesses up to 500 gsm. Its robust design and high-precision mechanism enable efficient handling of both lightweight and heavier sheet stocks.Q: When should you use a programmatic rotary sheet cutter in your production line?

A: Use this machine when high precision, high throughput, and consistent quality are required in sheet cutting processes. It is particularly beneficial in large-scale paper or board converting, packaging, and printing environments with repetitive cutting tasks.Q: Where is this machine typically installed and operated?

A: This rotary sheet cutter is most commonly used in commercial printing plants, paper and packaging converting facilities, or factories that require automated and accurate sheet cutting. Its compact footprint allows for integration into modern industrial settings.Q: What is the process of cutting sheets with this machine?

A: Sheets are automatically fed into the rotary cutter, where servo-driven blades shear the material at pre-programmed lengths and speeds. The PLC manages all operations, ensuring that each cut is highly accurate and consistent, while the fan air-cooled system maintains optimal machine temperature.Q: What are the primary benefits of using this fully automatic rotary sheet cutter?

A: Key advantages include rapid cutting speeds (up to 300 cuts per minute), high mechanical precision (0.5 mm), versatile material compatibility, reduced manual labor, energy efficiency, and consistent output quality. The automation boosts productivity and lowers the risk of operator error.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paper Roll To Sheet Cutting Machine Category

P.I.V. Reel to Sheet Cutter Machine

Price 425000.00 INR / Set

Minimum Order Quantity : 1 , , Piece

Capacity : Customisable Output Typical: 15,000 sheets/hour

Voltage : 220V / 380V

General Use : Sheet Cutting from Paper/Film/Nonwoven Rolls

Cutting Function : Other, Automatic Reel to Sheet Cutting

Digital Rotary Sheet Cutter

Price 425000.00 INR / Set

Minimum Order Quantity : 1 Piece

Capacity : Continuous Operation, 8 hours/day

Voltage : 220V / 50Hz

General Use : Accurate Sheet Cutting for Printing and Packaging

Cutting Function : Other, Automated Rotary Cutting

Paper Roll to Sheet Cutting Machine with 5 Roll Stand

Price 425000.00 INR / Set

Minimum Order Quantity : 1 , , Piece

Capacity : 5 roll stand, max 3000 kg load

Voltage : 380V / 415V, 3 Phase, 50 Hz

General Use : Cutting Paper Rolls into Sheets

Cutting Function : Other, Automatic roll to sheet

Hand Board Cutter Machine

Price 425000.00 INR / Set

Minimum Order Quantity : 1 Piece

Capacity : Single Sheet

Voltage : Not Required (Manual)

General Use : Cutting Paper Boards and Cardboards

Cutting Function : Other, Straight and Angular Cutting

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS