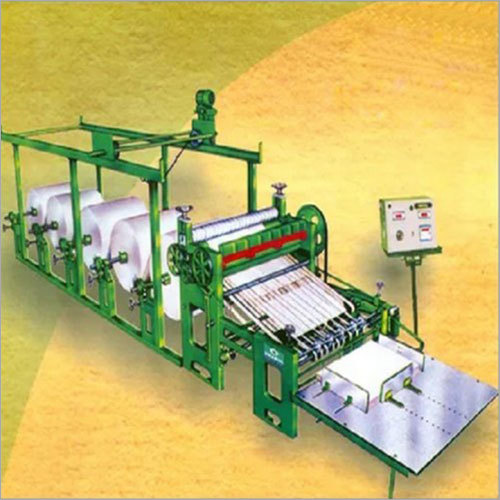

P.I.V. Reel to Sheet Cutter Machine

Price 425000.00 INR/ Set

P.I.V. Reel to Sheet Cutter Machine Specification

- Drive Motor

- Heavy Duty Induction Motor

- Product Type

- Sheet Cutting Machinery

- General Use

- Sheet Cutting from Paper/Film/Nonwoven Rolls

- Material

- Mild Steel Body, Heavy Duty Rollers

- Type

- Reel to Sheet Cutter Machine

- Capacity

- Customisable Output - Typical: 15,000 sheets/hour

- Weight (kg)

- Approx. 1600 Kg

- Computerized

- Yes

- Automatic

- Fully Automatic

- Cutting Speed

- 60 to 120 m/min

- Cutting Thickness

- Up to 5 mm (depends on material)

- Cutting Function

- Automatic Reel to Sheet Cutting

- Cooling System

- Air Cooling (optional water cooling on custom order)

- Drive Type

- Electric Motor Drive

- Voltage

- 220V / 380V

- Dimension (L*W*H)

- 3200 mm x 1300 mm x 1600 mm

- Feature

- High Precision Cutting, Robust Frame, Easy Operation

- Color

- Industrial Blue & Grey

- Motor

- 3 HP AC Motor

- Mechanical Precision

- 0.5 mm

- Software Detail

- PLC Programmed Automation

- Cutting Method

- Rotary Blade Cutting

- Control System

- PLC Touch Panel

- Cutting Material

- Paper, Film, Nonwoven, Laminates

- Cutting Area

- 1200 mm x 1800 mm

- Operator Interface

- Touch button/Selector switch

- Feeding Method

- Automatic unwinding from jumbo roll

- Safety Features

- Emergency stop, safety guards on moving parts

- Blade Material

- High carbon steel, ground finish

- Noise Level

- < 75 dB(A)

- Adjustable Sheet Length

- Yes (mechanical or digital setting depending on model)

- Surface Finish

- Powder coated/painted metal

- Accessories Included

- Basic tool kit, operation manual

- Power Consumption

- 3-4 kW

- Applicable Industry

- Printing, Packaging, Paper Conversion

- Installation Area Required

- Minimum 15 square meters

- Lubrication System

- Centralized manual lubrication

P.I.V. Reel to Sheet Cutter Machine Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 4 Pieces Per Month

- Delivery Time

- 45-60 Days

About P.I.V. Reel to Sheet Cutter Machine

PIV Reel to Sheet Cutter Machine is precisely designed in our own well-equipped production plant using the most up-to-date technology and equipment. Furthermore, we send these sheet cutting machine from our end after thoroughly inspecting them. Furthermore, our reputable customers can obtain the given range of PIV Reel to Sheet Cutter Machine in a variety of configurations at competitive prices. This machine has a simple setup and provides exceptional performance too. This machine is very cost-effective and can be easily customized as per the requirements.Efficient Reel to Sheet Conversion

Experience seamless transformation of jumbo rolls into precise sheets with the P.I.V. Reel to Sheet Cutter Machine. Its automatic unwinding and rotary blade cutting enable high-speed processing, ideal for industries needing both accuracy and productivity. The PLC control system empowers users with quick adjustments and streamlined operation for large-scale production.

Advanced Safety and Precision Engineering

Safety is embedded into every facet of the machine, featuring emergency stop mechanisms and safety guards around moving parts. High carbon steel blades and heavy-duty rollers ensure consistent, high-precision cuts, while extensive noise-reducing design provides a quieter working environment for operators.

Customizable and User-Friendly Design

From adjustable sheet length via mechanical or digital methods to robust construction and a touch-based operator interface, the P.I.V. Cutter meets diverse client needs. Its compact installation area and centralized manual lubrication system make maintenance simple, guaranteeing efficient integration into modern manufacturing environments.

FAQs of P.I.V. Reel to Sheet Cutter Machine:

Q: How does the automatic unwinding system of the P.I.V. Reel to Sheet Cutter Machine work?

A: The machine features an automatic unwinding system that feeds material directly from a jumbo roll into the cutting section, eliminating manual intervention and ensuring a continuous, efficient cutting process.Q: What types of materials can be cut using this machine, and what is the maximum cutting thickness?

A: The P.I.V. Reel to Sheet Cutter is suitable for cutting paper, film, nonwoven fabrics, and laminates, with a maximum cutting thickness of up to 5 mm, depending on material type.Q: Where is this sheet cutter typically installed, and what is the required installation area?

A: This machine is commonly used in printing, packaging, and paper conversion facilities. It requires a minimum installation area of 15 square meters to ensure safe operation and easy access for maintenance.Q: What are the primary benefits of using the P.I.V. Reel to Sheet Cutter in production lines?

A: Key advantages include high-precision, automated sheet cutting, low noise emission (<75 dB), quick setup with adjustable sheet lengths, robust build quality, safety features, and reliable PLC programmed automation for consistent output.Q: How can operators set or adjust the sheet length on this machine?

A: Sheet length can be easily set or adjusted through either a mechanical dial or a digital control on the PLC touch panel, depending on the specific machine model chosen.Q: What safety systems are in place to protect operators during use?

A: For operator protection, the machine is equipped with emergency stop switches and safety guards on all moving parts, reducing risks during daily operation.Q: When and how should the lubrication system be maintained?

A: The machine uses a centralized manual lubrication system. Operators should follow the schedule outlined in the operation manual for regular lubrication to ensure smooth functioning and longevity of all moving parts.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paper Roll To Sheet Cutting Machine Category

Digital Rotary Sheet Cutter

Price 425000.00 INR / Set

Minimum Order Quantity : 1 Piece

Cutting Speed : Up to 1200 mm/min

Software Detail : Proprietary Digital Cutting Software Compatible with Windows

Mechanical Precision : 0.1 mm

Feature : Other, HighPrecision, Digital Control, UserFriendly Interface

Paper Roll to Sheet Cutting Machine with 5 Roll Stand

Price 425000.00 INR / Set

Minimum Order Quantity : 1 , , Piece

Cutting Speed : 60 120 cuts/min

Software Detail : PLC controlled system

Mechanical Precision : 0.5 mm

Feature : Other, Heavyduty construction, high precision, energy efficient, easy operation

Hand Board Cutter Machine

Price 425000.00 INR / Set

Minimum Order Quantity : 1 Piece

Cutting Speed : Depends on Operator

Software Detail : Manual Operation

Mechanical Precision : 0.2 mm

Feature : Other, Heavy Duty, Portable, High Precision

Programmatic Rotary Sheet Cutter Machine

Price 425000.00 INR / Set

Minimum Order Quantity : 1 Piece

Cutting Speed : Up to 300 cuts/min

Software Detail : PLC based Control System

Mechanical Precision : 0.5 mm

Feature : Other, High precision, high speed, automatic operation

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free