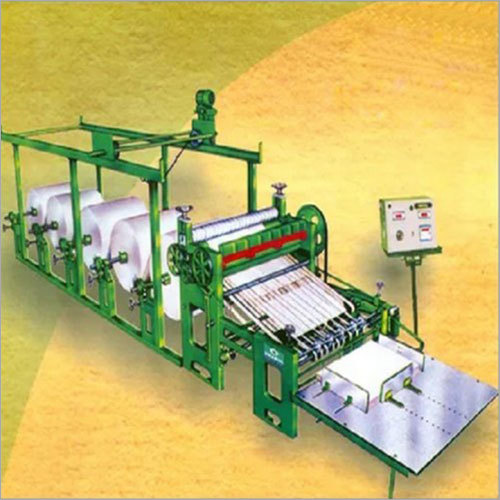

Hand Board Cutter Machine

Price 425000.00 INR/ Set

Hand Board Cutter Machine Specification

- Product Type

- Board Cutter Machine

- General Use

- Cutting Paper Boards and Cardboards

- Material

- Mild Steel Body, Hardened Steel Blade

- Type

- Hand Operated

- Capacity

- Single Sheet

- Weight (kg)

- Approx. 25 Kg

- Computerized

- No

- Automatic

- No

- Cutting Speed

- Depends on Operator

- Cutting Thickness

- Up to 5 mm

- Cutting Function

- Straight and Angular Cutting

- Drive Type

- Manual

- Voltage

- Not Required (Manual)

- Dimension (L*W*H)

- 700 mm x 250 mm x 250 mm

- Feature

- Heavy Duty, Portable, High Precision

- Color

- Light Blue / Grey

- Motor

- No Motor

- Mechanical Precision

- 0.2 mm

- Software Detail

- Manual Operation

- Cutting Method

- Manual Blade

- Control System

- Manual Handle

- Cutting Area

- 600 mm x 400 mm

- Cutting Material

- Paper Board, Card Board

- Surface Finish

- Powder Coated

- Application

- Printing Shops, Schools, Offices, Packaging

- Base Type

- Non-slip Surface

- Safety Feature

- Blade Guard Provided

- Handle Type

- Ergonomic Rubber Grip

- Blade Material

- High Carbon Steel

- Mounting

- Table-Top

Hand Board Cutter Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 4 Pieces Per Month

- Delivery Time

- 45-60 Days

About Hand Board Cutter Machine

High-Precision Manual Cutting

Experience superior accuracy with this hand-operated board cutter, designed for both straight and angular cuts. The robust hardened steel blade ensures a clean finish, making it suitable for diverse materials like paperboard and cardboard in printing shops or packaging units. Its structure emphasizes precision and durability, minimizing material wastage while maximizing productivity.

User-Friendly & Safe Design

Combining an ergonomic rubber grip with a secure non-slip base, the cutter ensures safety and comfort throughout manual operation. The integrated blade guard prevents accidental contact, making it reliable for frequent use in busy environments such as schools and offices. The powder-coated surface provides longevity and easy maintenance.

Versatile & Portable Construction

Built for portability and table-top use, this compact machine can be easily relocated or stored when not in use. Its approx. 25 kg weight, manageable dimensions, and absence of electrical or motorized components make it versatile for a variety of workspaces and requirements, from small office tasks to heavy-duty packaging operations.

FAQs of Hand Board Cutter Machine:

Q: How do I operate the Hand Board Cutter Machine?

A: To operate the machine, position your paper board or cardboard within the 600 mm x 400 mm cutting area, align the material for a straight or angular cut, lower the ergonomic handle to engage the blade, and smoothly press down. The non-slip base and blade guard ensure stability and safety throughout the process.Q: What materials and thickness can this cutter handle?

A: This cutter is designed for paper boards and cardboards with a cutting thickness of up to 5 mm. The high carbon, hardened steel blade offers high precision and is suitable for single-sheet cutting in printing shops, offices, packaging, and educational environments.Q: Where can the Hand Board Cutter Machine be used effectively?

A: It is ideal for use in printing shops, schools, offices, packaging industries, and similar environments where precise manual cutting of paper-based materials is required. Its table-top mounting and portable design make it easy to incorporate into different workflows.Q: What safety features are included with the machine?

A: For operator safety, the machine is equipped with a blade guard to prevent accidental contact, an ergonomic rubber grip to prevent hand fatigue, and a non-slip base to keep the unit steady during use. These features reduce the risk of workplace injuries.Q: What are the main benefits of using this manual cutter over electric alternatives?

A: Advantages include portability, zero power consumption, minimal maintenance, and precise manual control. It is also safer in environments where accidental electrical activation is a concern and is cost-effective for applications requiring single-sheet, high-precision cuts.Q: When is manual cutting preferred over computerized or motorized cutting systems?

A: Manual cutting is preferred when low-volume, high-precision, or specialty jobs are required, particularly for unique or custom sizes. It is also ideal where power sources are unavailable or when portability and immediate setup are necessary.Q: What is the maintenance process for the Hand Board Cutter Machine?

A: Routine maintenance includes regular cleaning of the powder-coated body and blade, checking for blade sharpness, and ensuring the handle and mounting bolts are secure. No motor or electric system means reduced upkeep compared to automated cutters.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paper Roll To Sheet Cutting Machine Category

Paper Roll to Sheet Cutting Machine with 5 Roll Stand

Price 425000.00 INR / Set

Minimum Order Quantity : 1 , , Piece

Weight (kg) : Approx 2200 kg

Motor : 5 HP main motor

Drive Type : Other, Electric motor with gear drive

Color : Other, Blue & grey

Digital Rotary Sheet Cutter

Price 425000.00 INR / Set

Minimum Order Quantity : 1 Piece

Weight (kg) : 135 kg

Motor : Brushless Servo Motor

Drive Type : Other, Servo Motor Drive

Color : Other, Industrial Grey with Black Accents

P.I.V. Reel to Sheet Cutter Machine

Price 425000.00 INR / Set

Minimum Order Quantity : 1 , , Piece

Weight (kg) : Approx. 1600 Kg

Motor : 3 HP AC Motor

Drive Type : Other, Electric Motor Drive

Color : Other, Industrial Blue & Grey

Programmatic Rotary Sheet Cutter Machine

Price 425000.00 INR / Set

Minimum Order Quantity : 1 Piece

Weight (kg) : 1800 kg

Motor : 4 kW (5 HP)

Drive Type : Other, Servo Motor Driven

Color : Other, Blue/Grey

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS